charpy impact test voltage to angle conversion|charpy impact testing definition : exporting Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM Resultado da 17 year old Russian kid residing in Austria, living the best life and making YouTube videos. Positive vibes only!

{plog:ftitle_list}

WEB1 de fev. de 2024 · By a piquant irony, Abigail Morris now finds herself at the receiving end of accusations about systemic inequality. This time the claims relate to class. She and her Last Dinner Party bandmates.

what is a charpy impact

The impact test calculator will help determine the energy absorbed by a notched material specimen. We perform impact tests to understand material failure behavior in dynamic conditions. Structures for transportation, military, and space applications undergo extreme .Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTMCharpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture .The Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. A pendulum in a Charpy impact test .

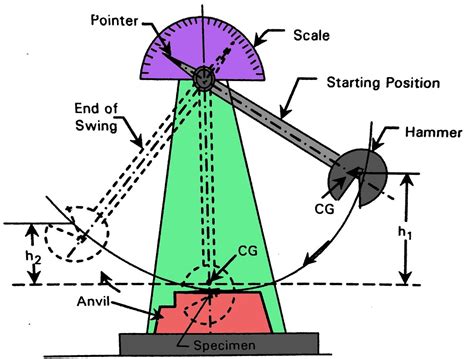

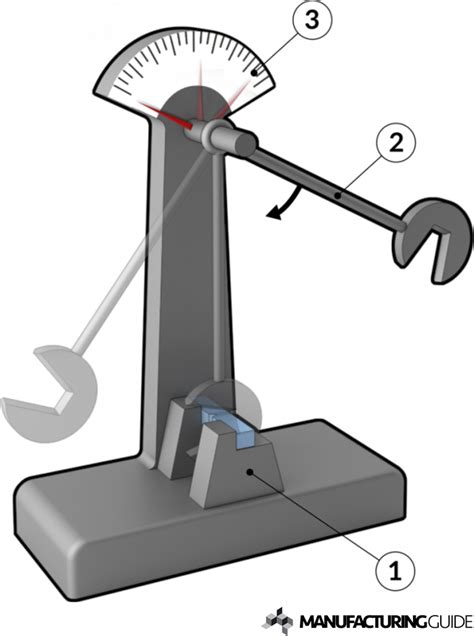

Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with body-centered-cubic (bcc) crystalline materials. These . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.

Lab-Potcher distributor

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .Charpy tests. Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the .The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. The Charpy Impact Test is a widely used single point test that measures the ability of a material to withstand impact from a swinging pendulum. The test determines the kinetic .

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . A V-shaped .Many notched bar impact tests of different designs and loading have been used to predict brittle fracture of ferritic steels. In the USA, the Charpy specimen has been standardized in ASTM E23 for impact three-point bend testing (ASTM E23 1999).Figure 1 illustrates a standard ASTM type A Charpy impact test specimen. The Charpy three-point bend specimen is more convenient .

In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the .The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. . A V-shaped notch, 2mm deep, with 45° angle and 0.25mm radius along the base. U-notch or keyhole notch – A 5mm deep notch with 1mm radius at the base of the notch. Fig 2 .Charpy impact test method for metallic materials is specified by European EN 10045 standard. . and tolerances in height are 0.11 mm for U and 0.06 mm for V notch test piece. Tolerances for angle between plane of symmetry of the notch and longitudinal axis of test piece as well as for angle between adjacent longitudinal faces of test piece are . The V-notch is commonly 2 mm deep with a 45° angle, providing a point of weakness where the impact occurs. Testing . allowing gravitational potential energy to convert into kinetic energy as it swings. Specimen Clamping: The test specimen, notched as per standards, is securely clamped at both ends. The notch is essential as it serves as the .

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount .

Charpy Impact Test Specimen Dimensions. A Charpy test specimen, which is placed horizontally into the machine, is typically a 55 x 10 x 10mm (2.165" x 0.394" x 0.394") bar with a notch machined into one of the faces.

Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. This value can be used to calculate the impact energy in J/m2 by dividing the joule value by the sample's cross-sectional area at the sample notch. The Charpy impact test (CVN) is still the most widely used test for evaluating the absorbed energy and transition temperature of line-pipe steels because of its simple testing method and fewer .mm in width and 55 mm in length and a V-shaped notch, 2mm deep, with 45° angle and 0.25mm radius along the base and specimen is fabricated (as required in the ISO 179/ASTM E23) is used for the finite element analysis. . This paper presents the results of Charpy impact test on Mild steel as measured impact force time history. A

charpy testing

An Izod impact testing apparatus — which is essentially identical to a Charpy impact testing machine — is used to determine Izod impact strength. The primary differences between the Izod and Charpy impact tests are the size of the test specimen, how it is restrained, and which side is struck by the pendulum hammer. A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after impact. . “The ratio of force and output voltage from the striker can change greatly during an impact that typically lasts from .

A Charpy impact test is crucial for analyzing the toughness of a material, and therefore important for ascertaining whether it can do a job or not. . The standard size of a specimen for Charpy impact testing is 10 mm × 10 mm × 55 mm. A 2mm deep notch with an angle of 45° and a tip radius of 0.25mm is then machined into one face of the bar .By testing plastics with the Charpy , IZOD test method the impact resistance of the plastic can be determined. Charpy and IZOD impact testing machine testercan also be used to determine the sensitivity of notched plastics specimens. . Impact blade angle radius: R=2mm: Izod Impact Test : Impact energy: 1J, 2.72J, 5.5J: 5.5J, 11J, 22J: 1J, 2 .The Charpy impact and notched impact test to ISO 179-1 and ISO 179-2 provide characteristic values for impact strength at high strain rates in the form of an area-related energy value. The tests are normally performed in normal . charpy U-notch impact test on metals. 0.3 The revision: a) b) c) following major modifications have been incorporated in this Scope of the standard have been modified to include all metals. In addition to the standard test piece, two- subsidiary test pieces having a width of 7.5 mm or 5 mm have been specified. Any of

The CFM to kW Calculator is helpful for you to let you convert airflow rates, in cubic feet measurement per minute (CFM) and power consumption displayed in kilowatts (kW) . Capacitor Output Voltage Calculator; Capacitor Value Calculator; . Charity Impact Calculator; Charpy Impact Test Calculator; Chart Percentage Calculator; A higher value of impact strength indicates a tougher material. Applications. Charpy Impact Test is an essential tool for quality control in various industries such as construction, aerospace, automotive, and manufacturing. This test can provide valuable information about a material's impact resistance, which is critical for designing and .

Charpy Impact Test: Izod Impact Test: Material Types: All metals, plastics, and composites: Metals, plastics, and composites: Notch Types: U and V-shaped notch: Only V-shaped notch: Material Position: Horizontal: Vertical: Striking Point: Middle of material: The upper Tip of the material: Material Dimensions: 55 x 10 x 10mm: 64 x 12.7 x 3.2mm .

The Class D Metals Impact Tester is a Single column impact testing system designed for Charpy Impact testing according to ASTM E23, ISO 148 and EN10045 industry standards. The Class D has has two popular models with peak capacities of 450J and 750J with optional pendulums for 150J, 300J, 450J and 600J.Plastics—Verification of pendulum impact-testing machines—Charpy, Izod and tensile impact-testing: ASTM: D6110: Charpy: Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics: D256: Izod: Standard Test Method for Determining the Izod Pendulum Impact Resistance of Plastics

The result of this work is NextGen’s line of impact test equipment, which includes combined systems covering the entire range of impact test energies: Class J – Charpy and Izod Automatic Impact Testing System – 1J – 50J; Class D – Dual Column Charpy Impact Tester – 150J, 300J, 450J, 600J or 750J.Test Method: Izod・Charpy: Initial Angle: 150° Test Capacity: Izod 1-12J ASTM Charpy 1-12J ISO Charpy 1-5J: Izod 1-25J Charpy 1-25J: 20-80% of the max. capacity is the suggested test range. Feature: Big indicator board for reading the impact energy directly. Standard pointer for users to read impact angle easily.Experiment 7: Charpy Impact Test Name: Om Prabhu Roll Number: 19D170018 Objectives: (a)To study the impact resistance of metals using impact testing machine of the Charpy type (b)To determine the variation of impact strength of a material with change in temperature Experimental Method:

charpy test calculator

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

Charpy V-Notch: 55 mm length, 10 mm width, 10 mm thickness, with a 2 mm deep notch and a 45° angle. Charpy U-Notch: 55 mm length, 10 mm width, 10 mm thickness, with a 1 mm radius and either a 2 mm or 5 mm depth. . Charpy Impact Tester is a dual-column system specifically designed for Charpy Impact testing in compliance with ASTM E23, ISO .

charpy impact testing pdf

WEBNa Apolar você tem toda a segurança para alugar imóveis, vender ou comprar imóveis. Com mais de 10.000 imóveis disponíveis e uma rede integrada com mais de 60 lojas, .

charpy impact test voltage to angle conversion|charpy impact testing definition